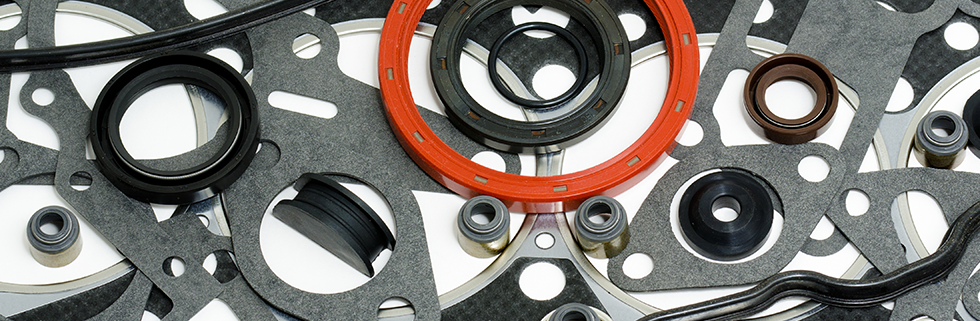

Our Capabilities:

Hecht Rubber Corporation is highly skilled in producing all manner of non-metallic products, including gaskets, adhesive-backed parts, molded rubber parts, tapes and custom component parts for a wide range of applications.

Our manufacturing capabilities include:

Engineering and design services

Material converting

Laminating – we can apply a wide range of adhesives to substrates to create products for “peel and stick” applications

Slitting – from thin films to dense elastomers, we will slit both plain or adhesive backed materials to your desired width and length specifications.

Cutting and Fabrication

Flatbed, rotary and stamping presses utilizing a wide range of tooling

High-tolerance waterjet cutting for prototyping and fast turnaround of complex parts

Secondary fabrication and parts assembly.

Rubber Molding

Precision molding of elastomeric seals, gaskets, bumpers and spacers

Wide range of rubber elastomers and durometers

Metal-inserted parts

Quality control and Packaging

Stringent quality control and inspection procedures

Custom packaging and labeling as required

Industries served:

Appliance

Automotive

Consumer Products

Construction

Defense

Electrical & Electronics

Glass and Glazing

Graphic Arts

HVAC

Hydraulics & Pneumatics

Instruments & Controls

Machinery & Equipment

Materials Handling

Marine

Medical

Recreational

Paper Manufacturing

Pharmaceutical

Telecommunications

Textile Manufacture

Woodworking & Millwork

Die-Cut Rubber Gaskets

Applications Across Industries:

Automotive: Ensuring reliable sealing in engines and various automotive components.

Aerospace: Vital for maintaining aircraft functionality in demanding conditions.

Electronics: Protecting sensitive electronic equipment from environmental factors.

HVAC: Essential for sealing HVAC systems for efficient operation.

Neoprene Gaskets:

Unparalleled resistance to oils and chemicals.

Offers premium quality and durability for industrial needs.

Preferred in applications where exposure to harsh substances is a concern.

Silicone Gaskets:

Designed for extreme heat environments.

Provides optimal performance under high-temperature conditions.

Widely used in industries with demanding heat-related requirements.

Viton Gaskets:

Extreme resistance to petroleum distillates, fuels and acids.

Engineered to withstand prolonged exposure to harsh chemicals.

Trusted in critical applications where chemical resistance is a requirement.

Extruded Rubber Gaskets

Sealing Properties:

Provide effective sealing against environmental elements.

Ensure leak-proof connections in various applications.

Versatile Design:

Available in different shapes, sizes, and materials to suit specific sealing needs.

Can be customized for unique requirements.

Durable Construction:

Made from high-quality rubber compounds for long-lasting performance.

Resistant to wear, tear, and extreme temperatures.

Common Applications:

Automotive industry: for sealing doors, windows, and compartments.

Construction sector: used in windows, HVAC systems, and pipelines.

Aerospace and marine industries: for sealing critical components.

Benefits:

Absorb vibrations and shocks.

Prevent contamination.

Reduce noise and provide insulation.

Easy to install and replace.

Cost-Effective Solution:

Offer an affordable sealing solution with low maintenance requirements.

Help in minimizing downtime and repair costs.

Environmental Resistance:

Withstand exposure to oils, chemicals, sunlight, and ozone.

Ideal for both indoor and outdoor applications.